Cable Design Service (CAD)

At ATAG we have a wealth of experience in the design, manufacture and supply of a wide range of quality, high performance and reliable cables for all types of industries. We can design cable to meet specific requirements, reverse engineer a product to provide innovative solutions including providing fault, contaminant, quality and cost analysis and carry out feasibility studies. Did you know 7/10 of our customers saved money and reported improved cable efficiency, performance, and life-span by using our service?

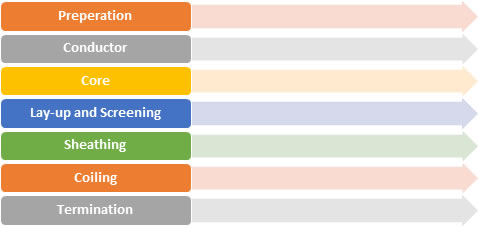

The cable design process consists of:

All of our cables are manufactured in the UK using quality materials and are available in a variety of colours, sizes and finishes to meet specific requirements.

Quality

The quality of a cable is integral to its performance, reliability and safety. This is paramount to all aspects of our cable design and manufacturing process. We carefully select and use only high quality ingredients and materials to ensure function and efficiency of the cables we manufacture.

Customer Specification

Once we have designed a custom cable we issue a customer specification design and approval form to ensure exact specifications and requirements have been met. This then includes an operators and production form which ensures product quality control and standards throughout the manufaction process.

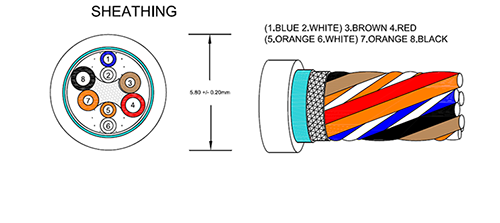

To view an example of one of our bespoke cable design please click here.

Featured Products

Curly Cords

We are the UK's largest manufacturer of curly cords and specialise in the design and manufacture of cords for a wide range of uses.

Please contact us for prices, specs and sizes.

Cathodic Protection

Cathodic protection cables provide strong protection against abrasion, chemicals, oils, moisture and crushing. Suitable for direct burial applications.

Please contact us for prices, specs and sizes.

Antimicrobial Cables

Our range of antimicrobial cables provide a solution to bacteria, fungus and mould which is ideal for hospitals, medical centres and cleanrooms.

Please contact us for prices, specs and sizes.